Fuselage

The

fuselage is the central body of an airplane and is designed to

accommodate the crew, passengers, and cargo. It also provides the

structural connection for the wings and tail assembly. Older types of

aircraft design utilized an open truss structure constructed of wood,

steel, or aluminum tubing. [Figure 2-5] The most popular types of

fuselage structures used in today’s aircraft are the monocoque (French

for “single shell”) and semimonocoque. These structure types are

discussed in more detail under aircraft construction later in the

chapter.

The

fuselage is the central body of an airplane and is designed to

accommodate the crew, passengers, and cargo. It also provides the

structural connection for the wings and tail assembly. Older types of

aircraft design utilized an open truss structure constructed of wood,

steel, or aluminum tubing. [Figure 2-5] The most popular types of

fuselage structures used in today’s aircraft are the monocoque (French

for “single shell”) and semimonocoque. These structure types are

discussed in more detail under aircraft construction later in the

chapter. Wings

The wings are airfoils attached to each side of the fuselage and are the main lifting surfaces that support the airplane in flight. There are numerous wing designs, sizes, and shapes used by the various manufacturers. Each ful.lls a certain need with respect to the expected performance for the particular airplane. How the wing produces lift is explained in Chapter 4, Aerodynamics of Flight.

Wings

may be attached at the top, middle, or lower portion of the fuselage.

These designs are referred to as high-, mid-, and low-wing,

respectively. The number of wings can also vary. Airplanes with a single

set of wings are referred to as monoplanes, while those with two sets

are called biplanes. [Figure 2-6]

Wings

may be attached at the top, middle, or lower portion of the fuselage.

These designs are referred to as high-, mid-, and low-wing,

respectively. The number of wings can also vary. Airplanes with a single

set of wings are referred to as monoplanes, while those with two sets

are called biplanes. [Figure 2-6] Many high-wing airplanes have external braces, or wing struts, which transmit the flight and landing loads through the struts to the main fuselage structure. Since the wing struts are usually attached approximately halfway out on the wing, this type of wing structure is called semi-cantilever. A few high-wing and most low-wing airplanes have a full cantilever wing designed to carry the loads without external struts.

The

principal structural parts of the wing are spars, ribs, and stringers.

[Figure 2-7] These are reinforced by trusses, I-beams, tubing, or other

devices, including the skin. The wing ribs determine the shape and

thickness of the wing (airfoil). In most modern airplanes, the fuel

tanks either are an integral part of the wing’s structure, or consist of

.exible containers mounted inside of the wing.

The

principal structural parts of the wing are spars, ribs, and stringers.

[Figure 2-7] These are reinforced by trusses, I-beams, tubing, or other

devices, including the skin. The wing ribs determine the shape and

thickness of the wing (airfoil). In most modern airplanes, the fuel

tanks either are an integral part of the wing’s structure, or consist of

.exible containers mounted inside of the wing.  Attached

to the rear or trailing edges of the wings are two types of control

surfaces referred to as ailerons and .aps. Ailerons extend from about

the midpoint of each wing outward toward the tip, and move in opposite

directions to create aerodynamic forces that cause the airplane to roll.

Flaps extend outward from the fuselage to near the midpoint of each

wing. The .aps are normally .ush with the wing’s surface during cruising

flight. When extended, the .aps move simultaneously downward to

increase the lifting force of the wing for takeoffs and landings.

[Figure 2-8]

Attached

to the rear or trailing edges of the wings are two types of control

surfaces referred to as ailerons and .aps. Ailerons extend from about

the midpoint of each wing outward toward the tip, and move in opposite

directions to create aerodynamic forces that cause the airplane to roll.

Flaps extend outward from the fuselage to near the midpoint of each

wing. The .aps are normally .ush with the wing’s surface during cruising

flight. When extended, the .aps move simultaneously downward to

increase the lifting force of the wing for takeoffs and landings.

[Figure 2-8]  With

the Federal Aviation Administration’s (FAA) recent addition of the LSA

category, various methods are employed to control flight and to produce

lift. These methods are discussed in Chapter 4, Aerodynamics of Flight,

which provides information on the effect controls have on lifting

surfaces from traditional wings to wings that use both flexing (due to

billowing) and shifting (through the change of the aircraft’s CG).

Handbooks specific to each category of LSA are available for the

interested pilot. LSA illustrate various lifting surfaces and control

methods. For example, the wing control aircraft is highly swept, and the

to provide controlled flight. [Figure 2-9]

With

the Federal Aviation Administration’s (FAA) recent addition of the LSA

category, various methods are employed to control flight and to produce

lift. These methods are discussed in Chapter 4, Aerodynamics of Flight,

which provides information on the effect controls have on lifting

surfaces from traditional wings to wings that use both flexing (due to

billowing) and shifting (through the change of the aircraft’s CG).

Handbooks specific to each category of LSA are available for the

interested pilot. LSA illustrate various lifting surfaces and control

methods. For example, the wing control aircraft is highly swept, and the

to provide controlled flight. [Figure 2-9]

Includes

the entire tail group and consists of as the vertical stabilizer and

the horizontal movable surfaces include the rudder, the or more trim

tabs. [Figure 2-10]

The

rudder is attached to the back of the vertical stabilizer. During

flight, it is used to move the airplane’s nose left and right. The

elevator, which is attached to the back of the horizontal stabilizer, is

used to move the nose of the airplane up and down during flight. Trim

tabs are small, movable portions of the trailing edge of the control

surface. These movable trim tabs, which are controlled from the flight

deck, reduce control pressures. Trim tabs may be installed on the

ailerons, the rudder, and/or the elevator.

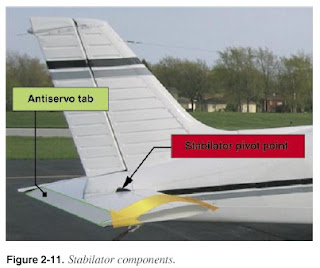

A second type of empennage design does not require an elevator. Instead, it incorporates a one-piece horizontal stabilizer that pivots from a central hinge point. This type of the weight-shift shifting of weight Empennage The empennage fixed surfaces such stabilizer. The elevator, and one design is called a stabilator, and is moved using the control wheel, just as the elevator is moved. For example, when a pilot pulls back on the control wheel, the stabilator pivots so the trailing edge moves up. This increases the aerodynamic tail load and causes the nose of the airplane to move up. Stabilators have an antiservo tab extending across their trailing edge. [Figure 2-11]

The antiservo tab moves in the same direction as the trailing edge of the stabilator and helps make the stabilator less sensitive. The antiservo tab also functions as a trim tab to relieve control pressures and helps maintain the stabilator in the desired position.

Landing Gear

The

landing gear is the principal support of the airplane when parked,

taxiing, taking off, or landing. The most common type of landing gear

consists of wheels, but airplanes can also be equipped with .oats for

water operations, or skis for landing on snow. [Figure 2-12]

The

landing gear is the principal support of the airplane when parked,

taxiing, taking off, or landing. The most common type of landing gear

consists of wheels, but airplanes can also be equipped with .oats for

water operations, or skis for landing on snow. [Figure 2-12] Airplanes with conventional landing gear are sometimes referred to as tailwheel airplanes. When the third wheel is located on the nose, it is called a nosewheel, and the design is referred to as a tricycle gear. A steerable nosewheel or tailwheel permits the airplane to be controlled throughout all operations while on the ground. Most aircraft are steered by moving the rudder pedals, whether nosewheel or tailwheel. Additionally, some aircraft are steered by differential braking.

The Powerplant

The

powerplant usually includes both the engine and the propeller. The

primary function of the engine is to provide the power to turn the

propeller. It also generates electrical power, provides a vacuum source

for some flight instruments, and in most single-engine airplanes,

provides a source of heat for the pilot and passengers. [Figure 2-13]

The engine is covered by a cowling, or a nacelle, which are both types

of covered housings. The purpose of the cowling or nacelle is to

streamline the flow of air around the engine and to help cool the engine

by ducting air around the cylinders.

The

powerplant usually includes both the engine and the propeller. The

primary function of the engine is to provide the power to turn the

propeller. It also generates electrical power, provides a vacuum source

for some flight instruments, and in most single-engine airplanes,

provides a source of heat for the pilot and passengers. [Figure 2-13]

The engine is covered by a cowling, or a nacelle, which are both types

of covered housings. The purpose of the cowling or nacelle is to

streamline the flow of air around the engine and to help cool the engine

by ducting air around the cylinders. The propeller, mounted on the front of the engine, translates the rotating force of the engine into thrust, a forward acting force that helps move the airplane through the air. The propeller may also be mounted on the rear of the engine as in a pusher-type aircraft. A propeller is a rotating airfoil that produces thrust through aerodynamic action. A low pressure area is formed at the back of the propeller’s airfoil, and high pressure is produced at the face of the propeller, similar to the way lift is generated by an airfoil used as a lifting surface or wing. This pressure differential pulls air through the propeller, which in turn pulls the airplane forward.

There are two significant factors involved in the design of a propeller which impact its effectiveness. The angle of a propeller blade, as measured against the hub of the propeller, keeps the angle of attack relatively constant along the span of the propeller blade, reducing or eliminating the possibility of a stall. The pitch is de.ned as the distance a propeller would travel in one revolution if it were turning in a solid. These two factors combine to allow a measurement of the propeller’s efficiency. Propellers are usually matched to a specific aircraft/powerplant combination to achieve the best efficiency at a particular power setting, and they pull or push depending on how the engine is mounted.